A modern workflow that integrates parametric mine design, advanced optimization algorithms, uncertainty and risk analysis, cloud-based collaboration and integrated sustainability considerations is redefining strategic mine planning. This integrated approach streamlines pit and phase optimization, design, scheduling, scenario analysis, and cross-functional collaboration. The result: reduced engineering effort and more robust plans that deliver measurable increases in net present value (NPV), while enhancing design precision and operational feasibility.

Evolving Challenges and Trends in Mine Planning

Planners increasingly prioritize faster, more adaptable mine plans, but achieving them has historically proven challenging. Optimization algorithms have evolved significantly, shaping both traditional methods, such as pit and phase optimization followed by scheduling, and more modern methodologies like direct block scheduling (DBS). While distinct in execution, both trends ultimately converge on similar challenges: producing practical, actionable results and doing so rapidly. For example, traditional methods often relied on manual or automated evaluations of revenue factor ranges, frequently leading to outputs that were difficult to operationalize and required multiple iterations. Meanwhile, modern approaches like DBS enable temporal pit extraction directly but still struggle to translate results into practical, implementable phases. When considering the need to better understand the sustainability impact of mining operations, the challenges become increasingly complex.

Integrating Strategic Planning and Design: A New Framework

Dassault Systèmes proposes an integrated framework that unifies strategic mine planning and design into a continuous, collaborative process. The framework consists of seven interrelated stages, including risk and uncertainty analysis, and leverages advanced algorithms, parametric modelling, and cloud-based data environments. Together, these components support a more adaptive, data-driven, and analytically rigorous approach to mine planning and execution.

Step 1: Early-Stage Optimization with Advanced Algorithms

Strategic planning begins with advanced optimization algorithms that generate initial pit shells, identify optimal phases, and evaluate scheduling scenarios. Techniques such as the updated Pseudoflow algorithm and direct block scheduling (DBS) enable rapid exploration of alternatives while honouring operational constraints and folding in sustainability considerations.

Step 2: Practical Phase Generation and Evaluation

Regardless of whether traditional methods or modern approaches like direct block scheduling (DBS) are used, planners face a common challenge: generating phases that are both practical and fast to produce. Dassault Systèmes addresses this with purpose-built tools and algorithms that create phase geometries in minutes. These tools account for operational parameters such as minimum mining widths, slope angles, size constraints, mining directions, and environmental factors, enabling planners to efficiently generate and compare multiple viable scenarios and select those offering the highest value and feasibility.

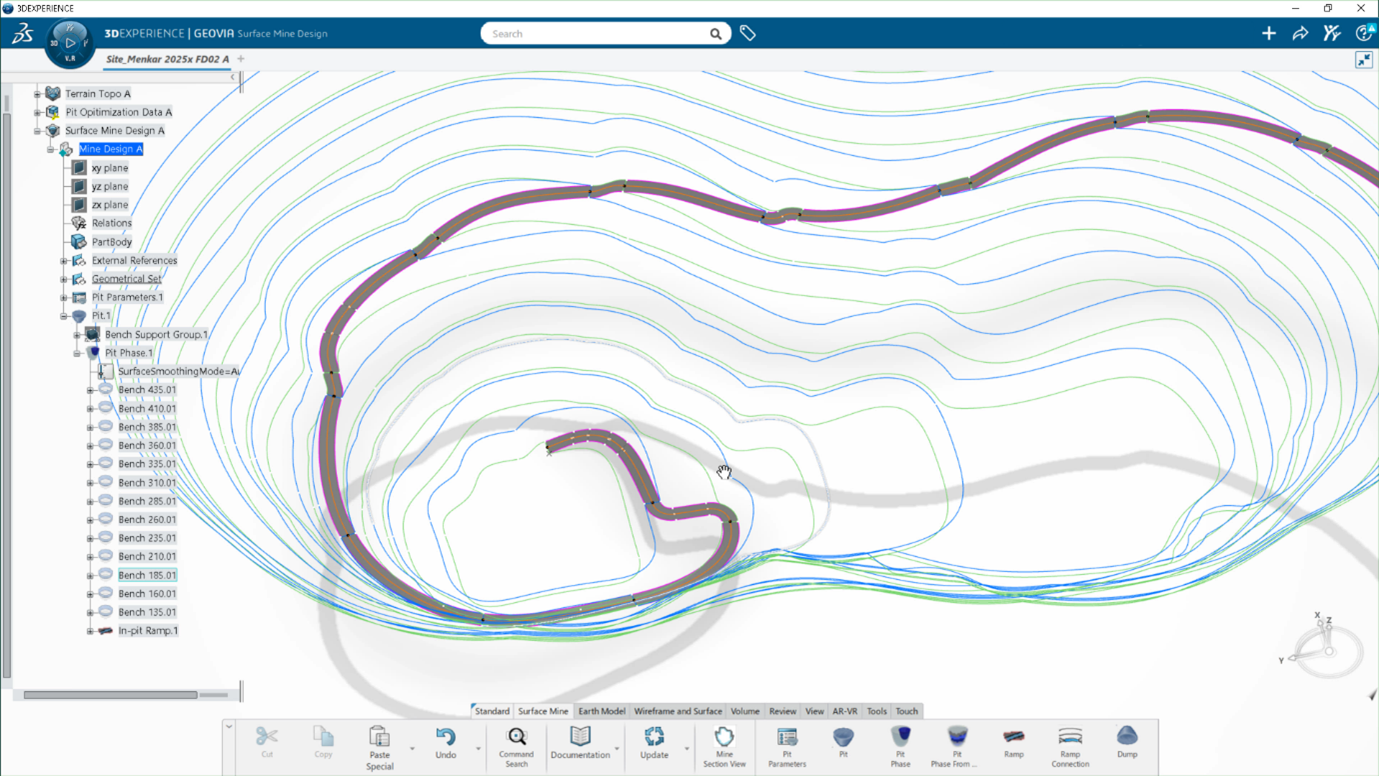

Step 3: Parametric and Generative Design Modelling

Once optimal phases are selected, parametric modelling technologies enable mine designs to be built and updated automatically based on defined rules and parameters. These tools minimize manual effort by automatically propagating changes across all design components. Generative design complements this process by allowing planners to explore multiple design variants driven by performance objectives and operational or sustainability constraints. Together, these approaches ensure a seamless, scalable, and sustainable transition from optimization to design.

Step 4: Integrated Data Management and Collaboration

All planning activities occur within a unified, cloud-based platform where block models, design parameters, and scheduling inputs are fully interconnected. This associativity ensures that changes made in one area can be reflected, propagating changes throughout the process, reducing errors and improving consistency. Teams collaborate in parallel, with real-time access to shared data and a single source of truth, enhancing coordination and accelerating decision-making across functions.

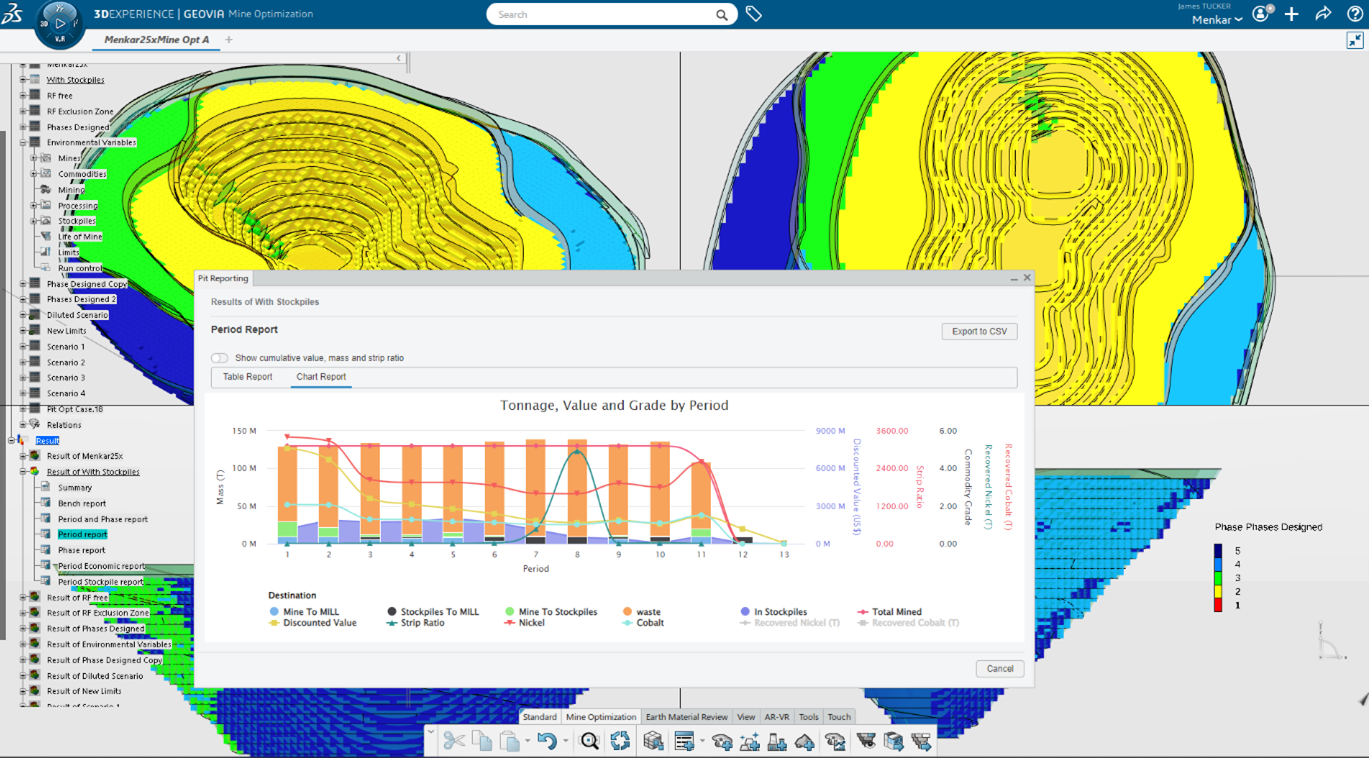

Step 5: Schedule Optimization Based on Operational Designs

The GEOVIA Mine Maximizer(GMX) engine—an advanced implementation of the Bienstock-Zuckerberg algorithm enhances strategic scheduling by enabling the evaluation and optimization of complex, multi-period scenarios. It efficiently manages precedence and capacity constraints, generating high-quality schedules in minutes. This rapid feedback loop empowers planners to perform iterative updates and stay aligned with evolving business and environmental objectives and changing design inputs.

Step 6: Risk Analysis and Robust Mine Planning

Incorporating risk and uncertainty into the planning process adds analytical depth and supports more resilient decision-making. This stage applies techniques such as Monte Carlo simulations, Design of Experiments, and sensitivity analyses to evaluate a wide range of scenarios and strategic options. Automating these analyses allows planners to explore hundreds of scenarios interactively and assess their impact on project feasibility. This approach helps identify robust strategies that perform effectively under varying conditions enhancing confidence and improving overall project reliability.

Case Study and Results

This case study evaluated whether the integrated framework combining advanced optimization algorithms, parametric design, and cloud-based data management could deliver measurable advantages over traditional methods. The results were compelling.

Compared to conventional approaches, design time was reduced from hours to minutes, and overall project execution time decreased by 70%. For a 20-period project with two million blocks, phase optimization was completed in about five minutes, scheduling in under ten, designs with ramps in roughly thirty minutes per phase, and design changes and updates in less than a minute to regenerate the design.

Improved optimization through rapid scenario analysis led to NPV increases of 5% to 25%, depending on project complexity and constraints. Economically, integrating advanced tools including the updated Pseudoflow algorithm, fast phase generation, parametric design, and GMX scheduling unlocked value increases reaching hundreds of millions of dollars.

Additional Benefits

This integrated framework also delivers key advantages:

- Reduces deviations from planned designs by generating realistic, executable phases.

- Supports sustainable planning by embedding ESG metrics directly into cost models and constraints.

- Improves collaboration and operational efficiency through a unified, cloud-based platform that gives all stakeholders access to a single source of truth.

Conclusions

The integration of advanced optimization algorithms, parametric and generative design technologies, and collaborative cloud-based data environments represents a paradigm shift in mine planning. These technologies reduce engineering time, elevate design quality, and unlock substantial economic value while fostering sustainability and cross-functional collaboration.

By adopting this integrated framework, mining companies can better achieve their financial targets and adapt quickly to changing conditions. Most importantly, these innovations don’t replace the expertise of mine planners they amplify it, enabling professionals to focus on high-value, strategic decisions that drive long-term success.

By Cristian Poblete, Senior Manager, GEOVIA R&D Apps Portfolio